Why is Supplier Performance Management important?

Supplier performance management is important for a number of reasons:

- It helps ensure that goods and services are delivered on time and meet quality standards. This is especially important in industries where timely delivery and high quality are crucial, such as in the manufacturing or healthcare sectors.

- It allows organizations to identify and address issues or problems with their suppliers before they have a negative impact on the business. This can help prevent delays, reduce costs, and improve overall efficiency.

- It helps organizations make better informed decisions about their supplier relationships. By tracking and analyzing supplier performance data, organizations can determine which suppliers are the most reliable and cost-effective, and prioritize their relationships accordingly.

- It can help organizations build stronger relationships with their suppliers. By working closely with suppliers to understand and address their needs, organizations can foster mutual trust and cooperation, which can lead to long-term partnerships.

A

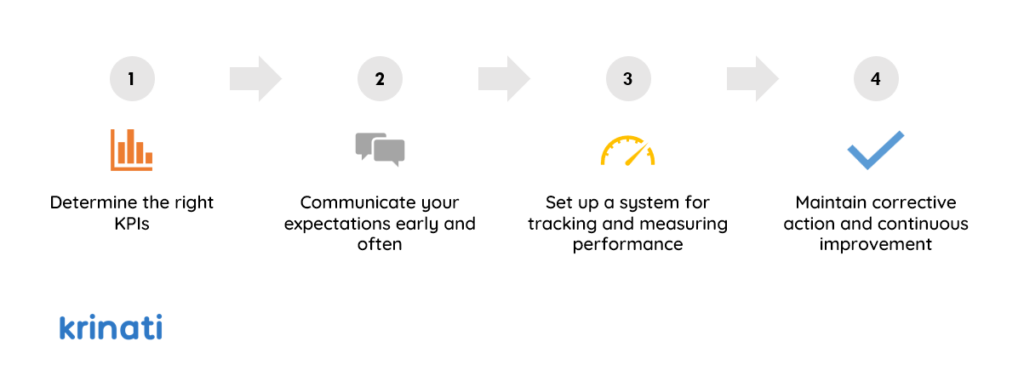

Here are 4 steps to make supplier performance management work better for your business.

A

1) Determine the right KPIs

While you establish the practice of monitoring supplier performance, the first step is to understand what you will measure. Determine the exact metrics you will use to evaluate and track supplier performance. This will help you make more informed decisions when evaluating and assessing supplier performance.

The metrics you use should be specific, measurable, and realistic. This will ensure that you’re able to accurately measure your suppliers’ performance and make changes when necessary. You should also take into account the impact each measure has on the overall performance of your business.

Typical performance KPIs include:

- On-time delivery

- Quality of product or service – SLA adherence or rejections on the assembly line

- Pricing terms

- Sustainability & Environment

- Risk & Stability – Reputation, Insurance, Financial Stability

A

2) Communicate your expectations early and often

Once you’ve determined the performance measures for tracking supplier performance, it’s important to be proactive in communicating with suppliers. Make sure that suppliers are aware of the metrics that will be used to measure their performance and how their performance will be tracked. This includes communicating your expectations about quality, cost, delivery timelines, and other key performance metrics. Ensure that suppliers are given enough information to allow them to make the necessary changes to meet your goals.

This proactive approach of communication with suppliers will create a culture of trust and ensure that everyone involved in the process understands their role in achieving success.

Additionally, you should establish regular intervals for evaluating supplier performance and make sure the data is collected and communicated with all stakeholders at these intervals.

3) Set up a system for tracking and measuring performance

Keeping track of and measuring supplier performance is important. A supplier performance scorecard is a great way to track and measure performance over time and make necessary corrections.

When setting up a supplier performance scorecard, there are several factors you should consider. For each measure, you should assign a numerical value that corresponds to a certain level of performance. Then, at regular intervals, you should gather data about how your suppliers are performing against these measures and determine the overall performance score for each supplier.

Choose a method for storing and organizing data, such as a spreadsheet or specialized software. For smaller organizations, spreadsheets work great. For more complex needs, specialized software solutions are available that can help with tracking and analyzing supplier performance data. These solutions may offer features such as automated data collection, real-time reporting, and the ability to track multiple suppliers and KPIs. By doing this, you can easily track trends in performance and make changes where needed.

A

4) Maintain corrective action and continuous improvement

Continuous improvement is a key part of supplier performance management. This means continually working with your suppliers to review current performance, discuss areas for improvement, and set new goals and objectives.

By taking necessary corrective action, you can ensure that your suppliers meet the standards you have set for them.

If a supplier is consistently underperforming, it’s important to have a plan in place to address the issue and take steps to improve performance. This could include reducing the order size, providing extra training or resources, or finding an alternative supplier.

For suppliers that consistently perform to set expectations, you need to put strategies in place to maintain their continued involvement with the organization; most often requiring one-on-one meetings with management personnel from both parties involved.