Manufacturing companies can gain measurable benefits from eSourcing. This guide shows you how to implement eSourcing effectively in manufacturing operations to improve efficiency, reduce costs, and build better supplier partnerships.

Essential Guidelines for eSourcing in Manufacturing

eSourcing tools have become central to modern manufacturing operations. Companies need robust electronic RFP management and bid review processes to stay competitive. Clear product specifications in RFPs form the foundation of successful sourcing initiatives. Manufacturing firms must focus on optimizing their raw materials and component sourcing while maintaining strong supplier relationships.

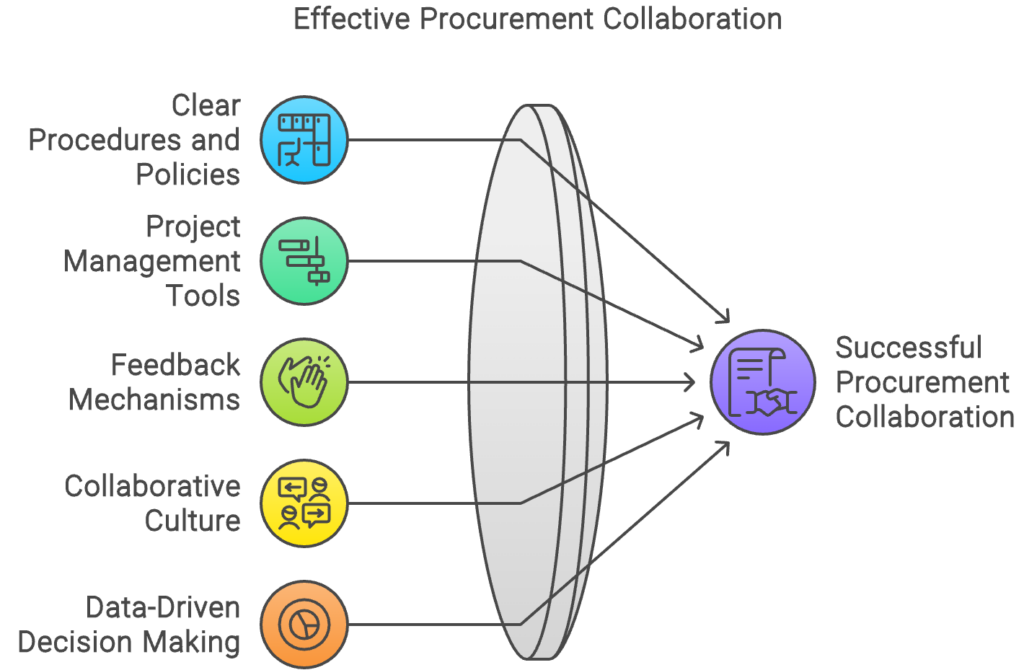

The success of eSourcing depends heavily on proper integration with existing procurement systems. Organizations should regularly evaluate their sourcing strategies and use data-driven decision-making processes. Early identification and resolution of problems through risk assessment helps prevent costly disruptions.

What is eSourcing in Manufacturing?

eSourcing modernizes purchasing through digital tools that manage supplier relationships, online auctions, and purchasing decisions. This modernization helps companies cut expenses, pick better suppliers, and run more efficiently.

Manufacturing organizations benefit from eSourcing when purchasing raw materials, building supplies, and production components. eSourcing platforms streamline everything from RFP creation to supplier selection and contract management. Digital processes reduce errors, save time, and provide data for better choices.

Choosing eSourcing Software

The right software selection makes a significant difference in sourcing success. Electronic RFP management, online Q&A capabilities, bid evaluation tools, and document control features should work together in one central system. This centralization helps procurement teams collaborate effectively and maintain clear oversight of all activities.

Software evaluation should prioritize user-friendliness, system compatibility, and scalability. The ideal solution simplifies work processes rather than adding complexity. Manufacturing companies should seek platforms with intuitive interfaces, comprehensive reporting capabilities, and features specifically designed for manufacturing needs.

Making RFPs More Effective

Creating effective RFPs requires attention to detail and clear communication. Technical specifications and quality standards must be precisely defined. The language should be accessible to all potential suppliers, avoiding industry jargon when possible. Including specific quantities, delivery schedules, and quality requirements helps prevent misunderstandings.

Digital RFP tools ensure consistency across all procurement activities. Clear evaluation criteria help suppliers understand how their bids will be assessed. Providing adequate response time results in more thoughtful and competitive proposals.

Working with Suppliers

Building strong supplier relationships requires systematic effort and attention. Organizations should maintain detailed supplier records that track performance history and capabilities. Regular platform training ensures suppliers can use the eSourcing tools effectively.

Good supplier relationships create tangible benefits. Organizations that treat suppliers as partners often receive preferential pricing and higher quality products. Regular communication and fair treatment form the basis of lasting partnerships.

Connecting Systems Together

Successful eSourcing requires seamless integration with ERP systems, Manufacturing Execution Systems, and other operational tools. Data synchronization across platforms ensures accuracy and provides comprehensive visibility into purchasing activities.

Single sign-on access simplifies system usage, while clear data management protocols maintain information integrity. Staff training on integrated systems ensures maximum benefit from the connected infrastructure. This integration enables better teamwork and more informed purchasing decisions.

Using Data for Better Decisions

Data analysis transforms sourcing effectiveness. Performance metrics provide insights into operational efficiency. Predictive analytics help anticipate future needs and optimize inventory levels. Regular supplier performance reviews inform strategic decisions about partner selection and development.

Market intelligence helps procurement teams track pricing trends and supply chain risks. Advanced analytics tools can automate supplier matching and bid evaluation processes, leading to faster and more objective decision-making.

Solving Common Problems

Implementation challenges require proactive solutions. Staff resistance can be overcome through comprehensive training programs and demonstrations of successful outcomes. Security concerns should be addressed by selecting platforms with robust protection features that comply with regulations like GDPR.

Supplier adoption improves when organizations offer incentives such as expedited payment terms. System integration succeeds with thorough testing and gradual implementation. External expertise can bridge internal knowledge gaps, while category-specific strategies address complex purchasing needs.

What’s Next in eSourcing

The future of eSourcing brings exciting possibilities. Artificial intelligence and machine learning will enable smarter purchasing decisions. Supply chain tracking will become more transparent and efficient. Sustainable procurement will gain importance as environmental concerns grow.

Risk management capabilities will expand with new technologies. Internet of Things integration will enable real-time material tracking, while advanced analytics will improve demand forecasting accuracy.

Final Thoughts

Effective eSourcing implementation brings substantial improvements in operational speed, cost control, and supplier collaboration. Success comes from combining the right tools with clear communication and data-driven decision-making.

Regular performance assessment and strategy adjustment ensure continued improvement. eSourcing becomes a catalyst for growth and innovation in manufacturing operations.

As manufacturing evolves, digital procurement helps organizations meet challenges and seize opportunities. These practices build resilient, efficient, and competitive supply chains ready for future demands.

Want to improve your manufacturing procurement? Start exploring eSourcing tools to enhance efficiency and reduce costs in your operations.