| Key Takeaways |

|---|

| Efficient supplier onboarding is vital for successful procurement strategies |

| Automated processes can reduce onboarding cycle times |

| Proper risk assessment and compliance are key components |

| Technology solutions are essential in streamlining the onboarding process |

| Effective onboarding improves supplier relationships and ROI |

| Clear communication and standardized procedures enhance efficiency |

| Ongoing improvement of the onboarding process yields long-term benefits |

| Integration with existing systems enables seamless supplier management |

Why Supplier Onboarding Matters

Supplier onboarding brings new vendors into your business. It’s essential for ensuring your procurement strategies are effective. When done well, it saves time, reduces risks, and improves collaboration with suppliers.

For high-risk suppliers, setup can take around 6 weeks. That’s considerable time. However, companies using advanced tools for supplier onboarding can complete the process much faster. This allows them to begin working with new suppliers sooner and accelerate operations.

Effective supplier onboarding isn’t just about speed. It builds a strong foundation for future collaboration. A well-executed onboarding process can enhance supplier performance, increase compliance, and foster strategic partnerships. This can result in cost reductions, better product quality, and innovation in your supply chain.

Explore our eSourcing solutions for efficient supplier management

Creating a Solid Onboarding Plan

To make supplier onboarding work well, you need a good plan. Start by thinking about what you want to achieve. Do you want to save time? Reduce risks? Make sure you’re following all the rules? Once you know your goals, you can create steps that everyone follows each time you bring on a new supplier.

Having a clear plan helps everyone know what to do. It’s like having a recipe for making a cake – if you follow the steps, you’ll get good results every time. This way, no matter who’s handling the onboarding, they’ll do it the same way and get the same good outcome.

A good onboarding plan should include several key parts:

- Initial supplier assessment and qualification

- Data collection and verification

- Risk evaluation and compliance checks

- Contract negotiation and management

- System integration and access provisioning

- Training and support for new suppliers

- Performance monitoring and feedback mechanisms

By addressing each of these areas systematically, you can ensure a thorough and effective onboarding process that sets the stage for successful supplier relationships.

Discover how to build credibility with suppliers

Gathering Supplier Information

The next big step is collecting information about your new suppliers. You’ll need to know things like their company name, what they sell, how to contact them, and their bank details for payments. It’s important to get all this info right from the start.

To make this easier, you can use online forms or special software. This way, suppliers can fill in their details themselves, which saves you time and helps avoid mistakes. It’s like using a digital form instead of paper – it’s faster and the information goes right where you need it.

When gathering supplier information, it’s important to balance getting enough data without overwhelming suppliers. Focus on essential information that directly impacts your ability to do business with the supplier. This might include:

- Legal company information and tax identification numbers

- Product or service catalogs with pricing details

- Certifications and compliance documentation

- Financial stability indicators

- References from other clients

- Key contact information for various departments (sales, support, accounts)

By making this data collection process simpler, you can reduce the time it takes to onboard new suppliers while still ensuring you have all the necessary information to make good decisions.

Streamline your data collection with our eSourcing tools

Checking Suppliers for Risks

Before you start working with a new supplier, it’s smart to check if there might be any problems. This is called risk assessment. You want to make sure the supplier is reliable, follows the law, and can deliver what they promise.

To do this, you might look at the supplier’s history, check their finances, or see if they’ve had any legal issues. It’s like doing homework on someone before you become friends with them – you want to know you can trust them.

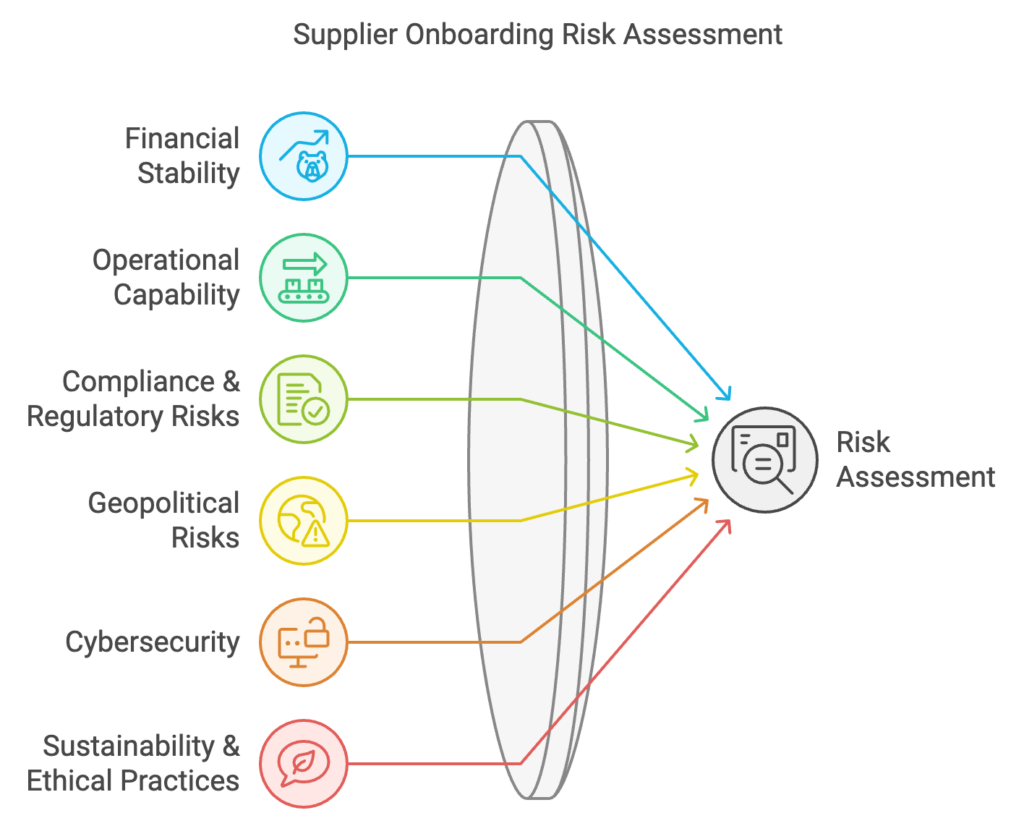

Risk assessment in supplier onboarding typically covers several key areas:

- Financial stability: Evaluating the supplier’s financial health to ensure they can fulfill long-term commitments.

- Operational capability: Assessing their ability to meet your volume and quality requirements.

- Compliance and regulatory risks: Checking for any legal issues or non-compliance with industry regulations.

- Geopolitical risks: Considering potential disruptions due to political instability in the supplier’s region.

- Cybersecurity: Evaluating the supplier’s data protection measures, especially if they’ll have access to your systems.

- Sustainability and ethical practices: Ensuring the supplier aligns with your company’s values and sustainability goals.

By thoroughly assessing these risk factors, you can make informed decisions about which suppliers to onboard and identify any areas that may require additional monitoring or support.

Learn about strategic sourcing best practices

Managing Contracts

Once you’ve checked out a supplier and decided to work with them, you’ll need to set up a contract. This is an agreement that says what the supplier will do for you and what you’ll do for them. It’s important to make this process smooth and quick.

Using digital tools can help a lot here. They can help you create contracts faster and make sure everyone follows the rules. It’s like using a template to write a letter – it helps you get it done right and quickly.

Good contract management is crucial for maintaining healthy supplier relationships and ensuring both parties meet their obligations. Here are some key aspects to consider:

- Standardized templates: Develop a set of standard contract templates for different types of supplier relationships to speed up the process.

- Clear terms and conditions: Ensure all contracts clearly outline expectations, deliverables, payment terms, and dispute resolution procedures.

- Performance metrics: Include specific, measurable performance indicators in the contract to facilitate future evaluations.

- Compliance clauses: Incorporate necessary compliance and regulatory requirements to protect your company.

- Review and approval workflows: Implement a streamlined review process involving legal, procurement, and other relevant departments.

- Electronic signatures: Use digital signature tools to expedite the signing process and reduce paperwork.

- Contract repository: Maintain a centralized, searchable database of all supplier contracts for easy reference and management.

By improving your contract management process, you can reduce the time it takes to onboard new suppliers while ensuring all necessary legal and business requirements are met.

Understand the importance of RFIs in supplier management

Connecting Systems

The last big step is to connect the new supplier to your company’s computer systems. This means making sure their information is in your databases and that you can easily order from them, track deliveries, and pay them.

This part can be tricky because different companies use different systems. It’s like trying to connect two phones that use different chargers – you might need a special adapter. But when it’s done right, it makes working with the supplier much easier.

System integration is a critical aspect of supplier onboarding that can significantly impact the efficiency of your procurement processes. Here are some key considerations:

- Data mapping: Ensure that supplier data fields align correctly with your internal systems to prevent errors and inconsistencies.

- API connections: Where possible, use Application Programming Interfaces (APIs) to enable real-time data exchange between your systems and the supplier’s.

- EDI implementation: For high-volume transactions, consider setting up Electronic Data Interchange (EDI) to automate order processing and invoicing.

- User access and permissions: Set up appropriate access levels for supplier users in your systems, ensuring they can access necessary information while maintaining data security.

- Testing and validation: Thoroughly test all integrations before going live to catch and resolve any issues early.

- Training and support: Provide comprehensive training to both your internal team and the supplier on how to use the integrated systems effectively.

By focusing on smooth system integration, you can create a seamless workflow that reduces manual effort, minimizes errors, and improves overall efficiency in your supplier relationships.

Explore our Reverse Auction solutions for seamless integration

Using Technology to Make Onboarding Easier

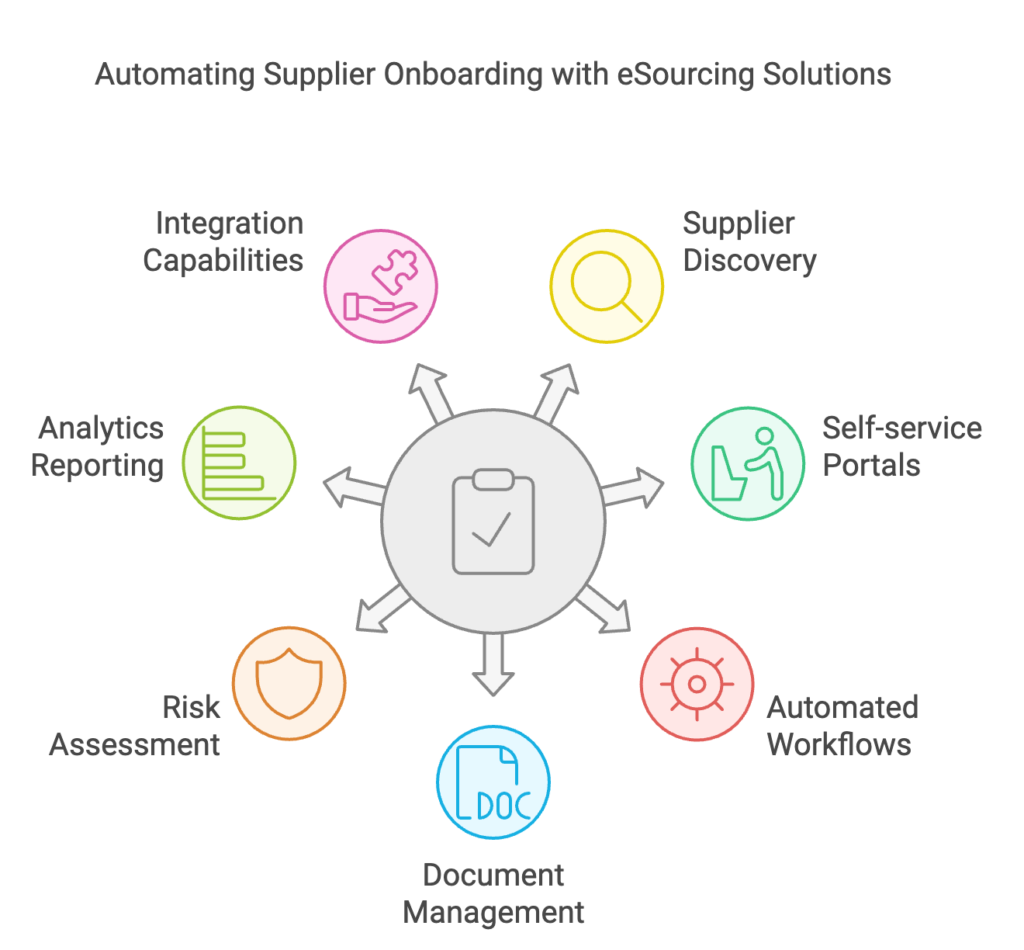

There are lots of cool tools that can help make supplier onboarding faster and easier. These are called eSourcing solutions. They can help with everything from finding new suppliers to setting them up in your systems.

Good eSourcing tools can help you collect supplier information, check for risks, create contracts, and even connect the supplier to your systems. It’s like having a Swiss Army knife for supplier onboarding – one tool that does lots of jobs.

Modern eSourcing solutions offer a range of features that can significantly streamline the supplier onboarding process:

- Supplier discovery: Tools to help you find and evaluate potential new suppliers based on your specific criteria.

- Self-service portals: Allow suppliers to input and update their own information, reducing the workload on your team.

- Automated workflows: Guide both your team and suppliers through each step of the onboarding process, ensuring nothing is missed.

- Document management: Centralized storage and version control for all supplier-related documents.

- Risk assessment tools: Automated checks against various databases to flag potential risks or compliance issues.

- Analytics and reporting: Dashboards and reports to track the progress of onboarding and identify bottlenecks.

- Integration capabilities: APIs and connectors to link the eSourcing platform with your other business systems.

By using these technological solutions, you can significantly reduce the time and effort required for supplier onboarding while improving accuracy and compliance.

Discover our comprehensive eSourcing solutions

Supplier Portals: A One-Stop Shop

A supplier portal is a special website where suppliers can log in to see and update their information, check orders, and communicate with your company. It’s like giving them their own dashboard for working with you.

Having a portal can make things easier for both you and your suppliers. They can update their own information, which saves you time. And they can easily see what’s going on with orders and payments, which can help avoid confusion.

A well-designed supplier portal can become a central hub for all supplier interactions, offering numerous benefits:

- Self-service capabilities: Suppliers can update their own information, reducing the workload on your procurement team.

- Document exchange: Secure sharing of important documents like contracts, certifications, and invoices.

- Performance tracking: Suppliers can view their own performance metrics and take proactive steps to improve.

- Communication channel: A centralized platform for all communications, reducing email clutter and improving response times.

- Order management: Real-time visibility into order status, delivery schedules, and inventory levels.

- Invoice and payment tracking: Suppliers can submit invoices and track payment status, reducing payment-related queries.

- Training and support: Access to training materials, FAQs, and support tickets to help suppliers navigate your processes.

By implementing a comprehensive supplier portal, you can enhance transparency, improve collaboration, and reduce the administrative burden on both your team and your suppliers.

Learn about the importance of digitalizing RFPs

Making Onboarding Automatic

Automating parts of the onboarding process can save a lot of time and reduce mistakes. For example, you can set up automatic reminders for suppliers to update their information, or have the system automatically check for any red flags when a new supplier is added.

Automation is like having a robot assistant that does the repetitive tasks for you. This leaves you free to focus on the more important parts of working with suppliers, like building good relationships and making smart decisions.

Automating the supplier onboarding process can yield significant benefits in terms of efficiency, accuracy, and consistency. Here are some key areas where automation can be particularly effective:

- Data validation: Automatically check submitted supplier information for completeness and accuracy.

- Risk assessments: Use AI-powered tools to scan databases and flag potential risks or compliance issues.

- Approval workflows: Automate the routing of supplier information to relevant stakeholders for review and approval.

- Document generation: Automatically create contracts and other necessary documents based on predefined templates and supplier information.

- System integration: Use robotic process automation (RPA) to transfer supplier data between different systems without manual intervention.

- Compliance monitoring: Set up automated checks to ensure suppliers maintain required certifications and comply with regulations.

- Performance tracking: Automatically collect and analyze supplier performance data to identify trends and issues.

By implementing these automation strategies, you can significantly reduce the time and effort required for supplier onboarding while minimizing errors and ensuring consistent processes across your organization.

Explore our automated supplier onboarding solutions

Measuring Success and Getting Better

To know if your supplier onboarding is working well, you need to measure it. You might look at how long it takes to onboard a new supplier, how many mistakes happen during the process, or how satisfied your suppliers are with the onboarding.

By looking at these numbers, you can see where you’re doing well and where you might need to improve. It’s like getting a report card – it shows you what you’re good at and what you need to work on.

Continuous improvement of your supplier onboarding process is crucial for maintaining efficiency and effectiveness. Here are some key metrics to track and strategies for improvement:

- Time-to-onboard: Measure the average time from initial contact to full integration. Look for ways to streamline each step of the process.

- Completion rate: Track the percentage of suppliers who successfully complete the onboarding process. Identify common drop-off points and address barriers.

- Data accuracy: Monitor the rate of errors or inconsistencies in supplier data. Implement better validation checks or provide clearer instructions to suppliers.

- Compliance rate: Measure how well suppliers meet your compliance requirements. Offer additional support or training in problem areas.

- Supplier satisfaction: Regularly survey suppliers about their onboarding experience. Use feedback to refine your processes.

- Cost per onboarding: Calculate the resources expended for each supplier onboarded. Look for opportunities to automate or simplify costly steps.

- System adoption rate: Track how quickly and effectively suppliers adopt your systems. Improve training materials or user interfaces if adoption is slow.

By consistently monitoring these metrics and acting on the insights they provide, you can continually refine your onboarding process, leading to better supplier relationships and more efficient procurement operations.

Discover how Krinati can help improve your procurement processes

Dealing with Common Onboarding Problems

Even with a good plan, you might run into some problems when onboarding suppliers. One common issue is getting good quality data from suppliers. Sometimes the information they give might be incomplete or out of date.

Another challenge can be getting suppliers to use new systems or processes. Some might be used to doing things a certain way and not want to change. To help with this, it’s important to explain the benefits of the new process and provide good support.

Here are some strategies to address common onboarding challenges:

- Incomplete or inaccurate data:

- Implement data validation checks in your supplier portal

- Provide clear instructions and examples for each data field

- Use AI-powered tools to cross-reference and verify supplier information

- Resistance to new systems:

- Offer comprehensive training and support materials

- Highlight the benefits of the new system for suppliers

- Consider a phased approach to system adoption

- Compliance issues:

- Clearly communicate compliance requirements upfront

- Provide resources to help suppliers meet standards

- Implement regular compliance checks and reminders

- Communication breakdowns:

- Establish clear points of contact for suppliers

- Use a centralized communication platform

- Set up automated status updates and reminders

- Integration difficulties:

- Conduct thorough testing before full implementation

- Offer technical support for integration issues

- Consider developing custom APIs for key suppliers

By proactively addressing these common challenges, you can create a smoother onboarding experience for both your team and your suppliers, leading to stronger and more productive relationships.

Learn how to build trust with suppliers during onboarding

Real-World Success: A Case Study

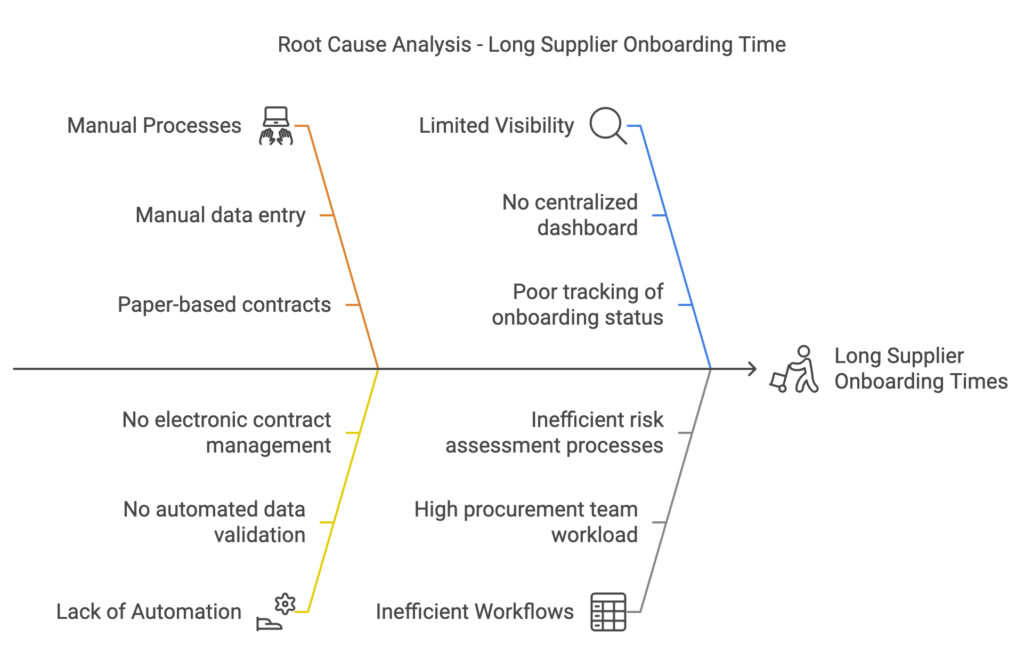

Let’s look at a real example of how streamlined supplier onboarding can make a big difference. A large manufacturing company was taking an average of 8 weeks to onboard new suppliers. This was causing delays in getting new products to market.

By implementing a new eSourcing solution and automating parts of their onboarding process, they were able to cut the onboarding time down to just 3 weeks. This helped them start working with new suppliers faster and get their products to market quicker.

Here’s a more detailed breakdown of the case study:

Industry: Global Electronics Manufacturer

Challenge: Long supplier onboarding times leading to product launch delays

Initial Situation:

- Average onboarding time: 8 weeks

- Manual data entry and verification

- Paper-based contracts and approvals

- Limited visibility into onboarding status

Solution Implemented:

- Deployed a comprehensive eSourcing platform

- Introduced a supplier self-service portal

- Automated data validation and risk assessment

- Implemented electronic contract management

- Created a centralized dashboard for tracking onboarding progress

Results:

- Reduced average onboarding time to 3 weeks

- 60% reduction in data entry errors

- 40% increase in supplier satisfaction scores

- 25% reduction in procurement team workload

- Ability to onboard 30% more suppliers annually

Key Learnings:

- Automation can significantly reduce manual workload and errors

- Self-service options empower suppliers and speed up the process

- Centralized tracking improves visibility and helps identify bottlenecks

- Standardized processes lead to more consistent outcomes

This case study demonstrates how the right combination of technology and process improvements can transform supplier onboarding from a bottleneck into a strategic advantage.

See how our eSourcing solutions transform procurement processes

The Future of Supplier Onboarding

As technology keeps improving, supplier onboarding is likely to get even faster and easier. We might see more use of artificial intelligence to help spot potential risks or suggest the best suppliers for a particular job.

Another trend is the use of blockchain technology to securely share and verify supplier information. This could make it easier to trust the data you’re getting from suppliers and reduce the need for repeated checks.

Looking ahead, several emerging technologies and trends are set to reshape supplier onboarding:

- Artificial Intelligence and Machine Learning:

- Predictive analytics for supplier performance and risk

- Automated contract analysis and optimization

- Intelligent chatbots for supplier support and queries

- Blockchain and Distributed Ledger Technology:

- Immutable records of supplier credentials and certifications

- Smart contracts for automated, condition-based payments

- Transparent and traceable supply chain transactions

- Internet of Things (IoT):

- Real-time tracking of supplier inventory and production capacity

- Automated quality control and compliance monitoring

- Predictive maintenance for supplier equipment

- Advanced Data Analytics:

- Deep insights into supplier performance across multiple dimensions

- Network analysis to identify optimal supplier ecosystems

- Scenario planning for supply chain resilience

- Advanced Data Analytics:

- Deep insights into supplier performance across multiple dimensions

- Network analysis to identify optimal supplier ecosystems

- Scenario planning for supply chain resilience

- Virtual and Augmented Reality:

- Virtual facility tours and audits

- Interactive training and onboarding experiences

- Augmented reality for remote supplier support

- 5G and Edge Computing:

- Ultra-fast, real-time data exchange with suppliers

- Enhanced mobile capabilities for on-the-go supplier management

- Edge processing for localized supplier interactions

As these technologies mature and become more integrated into procurement processes, we can expect supplier onboarding to become increasingly automated, intelligent, and seamlessly integrated with broader supply chain management systems.

Contact us to learn more about innovative supplier onboarding solutions

Wrapping Up

Streamlining supplier onboarding is a big step towards making your whole procurement process work better. By using the right tools, automating where you can, and always looking for ways to improve, you can make onboarding faster, easier, and more effective.

Remember, good supplier onboarding isn’t just about getting paperwork done. It’s about starting strong relationships with your suppliers that will help your business grow and succeed. With the right approach, you can turn supplier onboarding from a chore into a powerful tool for your business.

In conclusion, effective supplier onboarding is a critical foundation for successful procurement and supply chain management. By implementing a well-designed onboarding process that leverages technology, automation, and best practices, organizations can:

- Reduce time-to-value for new supplier relationships

- Minimize risks associated with supplier non-compliance or underperformance

- Improve data accuracy and consistency across procurement systems

- Enhance supplier satisfaction and engagement

- Free up procurement teams to focus on strategic activities

- Increase overall supply chain agility and resilience

As you continue to refine and optimize your supplier onboarding process, keep in mind that it’s an ongoing journey of improvement. Stay informed about emerging technologies and industry trends, regularly solicit feedback from both suppliers and internal stakeholders, and be willing to adapt your processes as needed.

By making supplier onboarding a priority and investing in its continuous improvement, you’ll be laying the groundwork for stronger, more productive supplier relationships that can drive significant value for your organization in the long term.